Technical requirements on this stainless steel globe valves:

1. Design and Manufacture: ASME B16.34

2. Face to Face: ASME B16.10

3. Flange End: ASME B16.5

4 Test: API 598

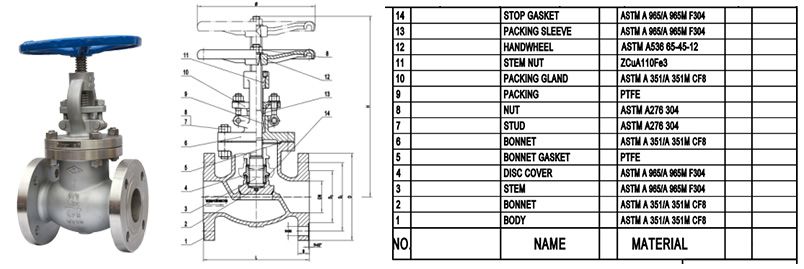

Product Details

| Parts Name | Materials |

| Body、Bonnet | ASTM A351 |

| Disc | ASTM A351 |

| Stem | ASTM A965 |

| Seat Ring | ASTM A351 |

Yuanda Valve Company's globe valves are mainly used to stop, start and regulate the flow of fluid in pipelines. Shut-off valves can be used to shut off fluid flow by moving the valve flap against the direction of flow. These valves are particularly common in switching service, but can also be used in a variety of applications. Yuanda Valve manufactures stainless steel globe valves, as well as a variety of other material types, including cast iron, cast steel, and bronze. This includes corrosion resistant, pressure sealed and cryogenic globe valves. If you have any questions about our globe valve products and their features, please contact Yuanda Valve today!

1. Design and Manufacture: ASME B16.34

2. Face to Face: ASME B16.10

3. Flange End: ASME B16.5

4. Stainless Steel Globe Valve Standard Test: Conforms to API 598

In these applications, corrosion, corrosion and other conditions of use will indicate the need for thick-walled parts and larger rod diameters.

1. Bolt cover;

2. Pressure sealing valve cover;

3. External screws and forks;

4. Rotating rising stem and non-rotating rising stem;

5. Ascending handwheel and non-rising handwheel;

6. Straight type, Y type, right angle type;

7.stop-check (nonreturn type globe valves in which the disc may be positioned against the seat by action of the stem but is free to rise as a check valve due to flow from under the disc when the stem is in a full or partially open position);

8.plug, narrow, conical, ball, or guided disc;

9.metallic seating surfaces;

10.flanged or butt-welding ends.

11.It covers valves of the nominal pipe sizes NPS:

2, 2½, 3, 4, 6, 8, 10, 12, 14, 16, 18, 20, 24;

12.corresponding to nominal pipe sizes DN:

50, 65, 80, 100, 150, 200, 250, 300, 350, 400, 450, 500, 600;

13.applies for pressure class designations:

150, 300, 600, 900, 1500, 2500.

Stainless Steel Globe Valve is used to regulate fluid flow and cut off the fluid (even for shut-off operations, ball valves and gate valves should always be preferred). Stainless Steel Globe Valves is a two-way valve, different from a check valve, which means that fluid can flow in the valve in any way.

1. Unique non-rotating stem design is easily adaptable for actuation-- with precision Acme threads and burnished finish. Stainless Steel Valve suitable for horizontal installation.

2. Stainless Steel Universal trim: 13Cr stem, 13Cr faced disc, and CoCr alloy faced seats-- API Trim 8 suitable for service up to 850 F(454 C). Seat face CoCr alloy hardfaced, ground, and lapped to a mirror finish . Conical seat machined to fine surface finish. Body guided disc accurately mates the hardfaced surface of the disc (hardfaced with 13Cr, CoCr alloy, SS 316, or Monel) with the surface of the body seat, which is ground and lapped to a mirror finish. The disc guides are hardfaced to extend the wear life of the disc guides.

3. Stainless Steel Body and bonnet castings are precision machined. One-piece bonnet for better alignment, fewer parts.

4. Stuffing box machined to fine surface finish.

5. Body and bonnet joint accurately machined to fine surface finish. Fully enclosed gasket.

6. Gland has two-piece construction for easy alignment.

7. Rotating stem nut in Austenitic ductile iron Gr. D-2C, renewable in-line.

8. Torque arm reduces wear on packing rings and enables better sealing and reduces torque.

9. Impactor handwheels: Globe and stop check valves require higher closing torques than gate valves with the same seat diameter and pressure class. The most economical mechanism for tight shutoff is the impactor handwheel. Two lugs cast under the wheel strike simultaneous blows and give 3 - 10 times the closing force of standard handwheels. Impactor handwheels are supplied at manufacturer's option unless specified by customer.

10. Flanges: ASME Classes: 150-- 300: 116" raised face.

11. ASME Classes: 600-- 1500: 1/4" raised face.

12. Finish: 125-- 250 AARH for all valves.

1. The cooling water system that needs to adjust the flow rate.

2. Fuel system, flow regulation, and tightness are very important.

3. When tightness and safety are the main considerations, high-point vents and low-point drains.

4. Water supply, chemical feed, condenser exhaust and exhaust drainage system.

5. Boiler discharge port and drain pipe, main steam discharge port and drain pipe, and heater drain pipe.

6. Turbine seals and drain pipe.

7. Turbine lubricating oil system, etc.

Will Stainless Steel Valves Rust?