Home >> Products >> KS-JIS Standard >> Stainless Steel >> Check Valve >> KS Stainless Steel Swing Foot Valve

1. Design and Manufacture:

2. Face to Face:

3. Flange End:

4. Test:

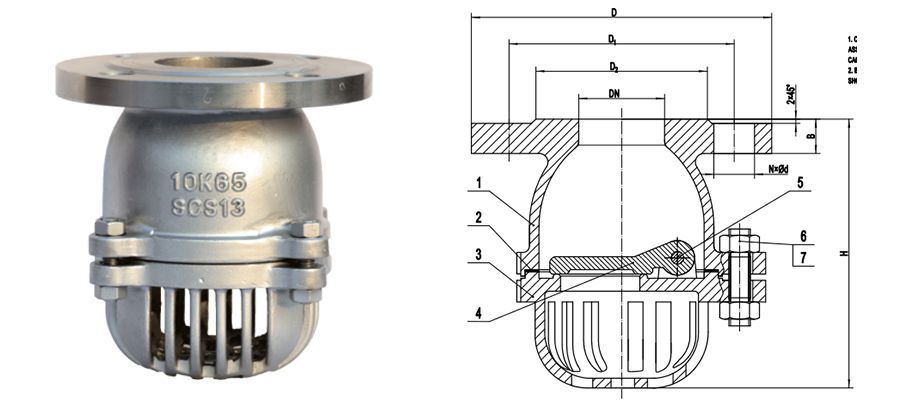

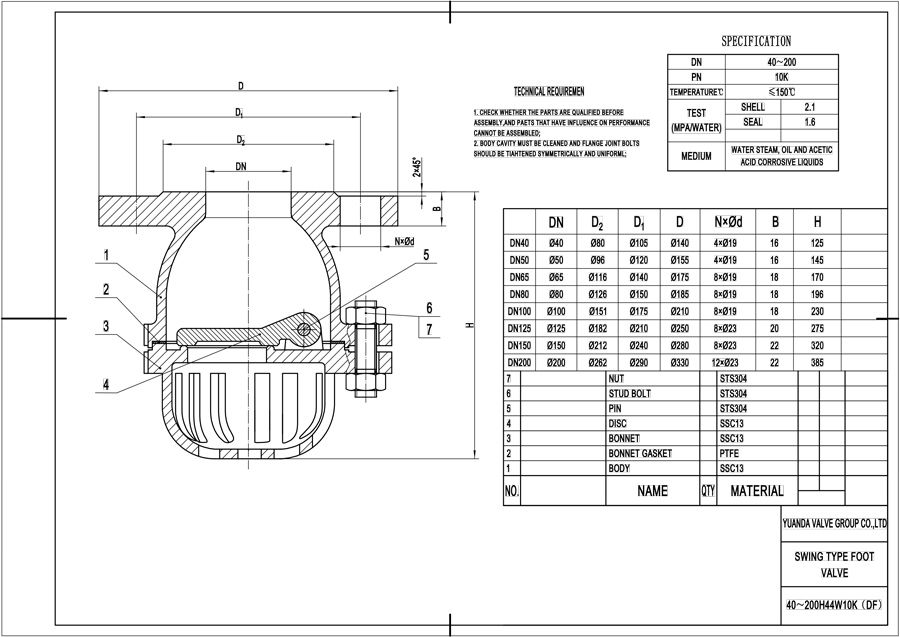

Product Details

| Parts Name | Materials |

| Body、Bonnet | SCS13 |

| Disc | SCS13 |

| Pin | STS304 |

| Packing | PTFE |

Utilizing a swing structure for effective filtration of impurities.

Suitable for mediums such as water, steam, oil, and corrosive liquids like acetic acid.

A swing foot valve is a valve used to control the flow of fluid in a piping system. You can install it at the bottom of the pump suction line and is designed to allow fluid to flow into the pump while preventing it from flowing back. The valve consists of a hinged baffle or disc that swings open when the fluid flows in and closes when the fluid stops. This type of valve is typically used in irrigation systems, water treatment plants and other applications where reliable fluid flow is required. These valves are designed to be operated by foot, hence the name "foot valve".

Swing check valves typically feature a spherical valve body with a hinged valve disc to prevent backflow. The seat is usually a full-port straight-through design. YUANDA offers various types of swing check valves for water and wastewater applications.

Swing check valves are commonly recommended for water and wastewater system applications due to their simple structure, low valve head loss, and ease of on-site maintenance.

Swing check valves are available with either metal-to-metal or resilient seats. It is generally advisable to use resilient seat swing check valves in wastewater or fluid services where debris or other particles may be present and forced closure is necessary.

Typically, the operation of swing check valves relies on gravity (the weight of the valve disc) and reverse flow. The pivot point of the swing check valve is located outside the periphery of the valve disc, and the greater the flow velocity and head pressure, the greater the closing force on the valve. To prevent valve disc impact and reduce hydraulic shock, external hinge arms can be equipped with lever weights or adjustable springs.

Our range of foot valve products includes the highly efficient swing foot valve and swing type foot valve, both designed to prevent backflow in pumping systems. When comparing a foot valve vs check valve, the foot valve stands out for its ability to maintain prime while drawing water. For enhanced filtration, we offer a foot valve with strainer hinged disc. Explore the various foot valve types we provide, including the durable stainless steel foot valve, built to last in demanding environments.