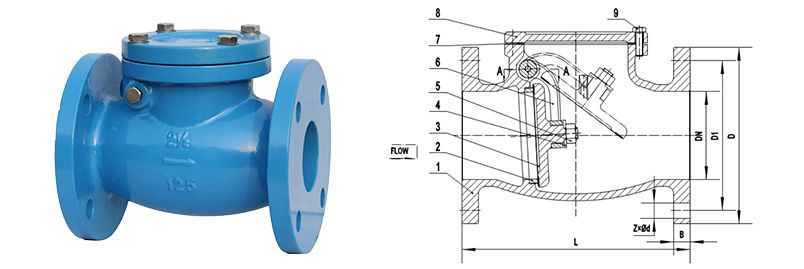

Home >> Products >> API-ANSI Standard >> Cast Iron >> Check Valve >> ANSI Cast Iron Swing Check Valve

Yuanda Valve Group produces cast iron swing check valves, which are well-structured and cost-effective, and are designed with replaceable valve seats and discs. Yuanda's cast iron swing check valve is suitable for various applications. Recommended for commercial and industrial steam, water, oil and gas services.

Product Details

1. Design and Manufacture

2. Face to Face: ANSI B16.10

3. Flange End: ANSI B16.1

4 Test: MSS-SP-71

The valve is a Class 125 (200 CWP) iron body check valve with flanged ends, bolted to the bonnet, and bronze installation. Cast iron swing check valves prevents backflow by automatically closing when the flow is reversed.

It conforms to the MSS-SP71 standard, and has an updateable disk and seat. It is equipped with a bolted valve cover for easy maintenance. Swing check valve can be installed in a horizontal position (or vertical upward flow)

| Parts Name | Materials |

| Body、Bonnet | ASTM A126 B |

| Disc | ASTM A126 B |

| Stem | SS420 |

| Seat Ring | Brass |

1. Renewable seat pan

2. Bolt type engine cover

3. Iron disc with bronze disc face ring and disc bolt

4. Bronze inlay

5. 125 psi/8.6 bar saturated steam to 353 degrees Fahrenheit

6. Synthetic fiber gasket

7. With Proper Machining Capabilities.

8. Not to be used for reciprocation air compressor applications.

The Swing Check Valve is a pivotal component in fluid control systems, ensuring seamless and efficient operation. In the realm of swing check valves, those manufactured in China, particularly the Cast Iron Swing Check Valve, stand out for their robust design and adherence to stringent technical requirements.

Designed and manufactured with precision, the Cast Iron Swing Check Valve meets top-notch technical standards. Its key specifications include:

Design and Manufacture: Crafted to exacting standards, ensuring reliability and longevity.

Face to Face: Conforming to ANSI B16.10, guaranteeing compatibility in various setups.

Flange End: Built to ANSI B16.1 specifications for secure and dependable flange connections.

Test: Complies with MSS-SP-71 standards, ensuring rigorous testing for optimal performance.

Key Components and Materials:

The Cast Iron Swing Check Valve comprises essential parts made from high-quality materials:

Body, Bonnet: Constructed from durable ASTM A126 B material, ensuring resilience in varied conditions.

Disc: Also made of ASTM A126 B, the disc is a crucial element for maintaining flow control.

Stem: Crafted from SS420, providing corrosion resistance and mechanical strength.

Seat Ring: Featuring a seat ring made of brass, enhancing the valve's sealing capabilities.

Noteworthy Features:

Renewable Seat Pan: The valve boasts a renewable seat pan, allowing for prolonged use and easy maintenance.

Bolt-Type Bonnet Cover: Facilitating convenient access for maintenance, ensuring swift and efficient service.

Bronze Inlay: The incorporation of bronze inlay enhances the valve's durability and resistance to wear.

Steam Capabilities: With a rating of 125 psi/8.6 bar, the valve is designed to handle saturated steam up to 353 degrees Fahrenheit.

Synthetic Fiber Gasket: Equipped with a synthetic fiber gasket, further ensuring a secure seal and preventing leaks.

Proper Machining Capabilities: Engineered with precision machining capabilities, guaranteeing optimal performance in diverse applications.

Application Caution: While versatile, it is important to note that this valve is not suitable for reciprocating air compressor applications.

In summary, the Swing Check Valve, particularly the Cast Iron variant from China, embodies technical excellence and reliability. Its robust construction, adherence to standards, and innovative features make it an ideal choice for fluid control in various industrial applications.