Home >> YUANDA Valve

Check valve refers to the opening and closing member for the circular valve and by its own weight and media pressure to produce action to block the backflow of the medium of a valve. Belong to the automatic valve category, also known as check valve, check valve, backflow valve or isolation valve. The valve movement is divided into lift and swing type. Lifting check valve and globe valve structure is similar, only the lack of driven valve valve stem. The medium flows in from the inlet side (lower side) and out from the outlet side (upper side). When the inlet pressure is greater than the sum of the weight of the valve flap and its flow resistance, the valve is opened. Conversely, the valve closes when the medium flows backwards. Swing check valve has an oblique and can rotate around the axis of the valve flap, the working principle is similar to the lift check valve. Check valve is often used as the bottom valve of the pumping device, can stop the backflow of water. Check valve and shut-off valve used in combination, can play a role in the safety of isolation. The disadvantages are high resistance and poor sealing when closed.

Check valves can also be used to provide recharge to auxiliary systems in which the pressure may rise above the system pressure. Check valves can be mainly divided into swing check valves (rotating according to the center of gravity) and lift check valves (moving along the axis).

The function of this type of valve is to allow the medium to flow in one direction only, and to prevent the flow in the opposite direction. Usually this valve is automatic work, in one direction of flow of fluid pressure, the valve flap open; fluid flow in the opposite direction, by the fluid pressure and the self-weight of the valve flap combined flap act on the valve seat, thus cutting off the flow.

Among the check valve belongs to this type of valve, it includes swing check valve and lift check valve. Swing check valves have a hinge mechanism and a door-like flap that rests freely on the inclined seat surface. To ensure that the flap reaches the right position on the seat surface every time, the flap is designed in the hinge mechanism so that the flap has sufficient swing space and true, full contact with the seat. The valve may be made entirely of metal, or may be inlaid with leather, rubber, or synthetic coverings, depending on the performance requirements. Swing-open check valves, in the fully open condition, are virtually unobstructed by fluid pressure, so the pressure drop through the valve is relatively small. Lift check valves have a valve flap that sits on the seat sealing surface on the valve body. This valve is like a globe valve except that the valve can be raised and lowered freely. The fluid pressure causes the valve to lift off the seat sealing surface and the media backflow causes the valve to fall back onto the seat and cut off the flow. Depending on the conditions of use, the flap can be of all-metal construction or in the form of a rubber gasket or rubber ring inlaid on the flap frame. Like globe valves, the passage of fluid through the lift check valve is narrow, so the pressure drop through the lift check valve is somewhat greater than that of swing check valves, and the flow rate of swing check valves is rarely restricted.

The opening and closing parts rely on the force of the media flow to open or close the valve to prevent the backflow of the media is called check valve. Check valve belongs to the automatic valve category, mainly used for one-way flow of media on the pipeline, allowing the media to flow in one direction only, in order to prevent accidents.

Structure classification

According to the structure, can be divided into lift check valve, swing check valve and butterfly check valve three kinds:

1. Lift check valve is divided into two types: vertical and horizontal.

2. Swing check valve is divided into single valve, double valve and multi-flap type.

3. Butterfly check valve for straight-through type.

The above check valves can be divided into four types of connection: threaded, flange, welded and clamped.

Material classification

1.cast iron check valve

2. Brass check valve

3. Stainless steel check valve

4. Carbon steel check valve

5.Forged steel check valve

Function classification

1.DRVZ silent type check valve

2.DRVG silent check valve

3.NRVR mute check valve

4.SFCV rubber flap check valve

5.DDCV double flap check valve

A, swing check valve: swing check valve flap is disc-shaped, rotating movement around the axis of the valve seat channel, because the valve channel into a streamline, flow resistance than lift check valve is small, suitable for low flow rate and flow does not often change the large diameter occasions, but not for pulsating flow, its sealing performance is not as good as lift type. Swing check valve is divided into single-valve, double-valve and multi-flap three, these three forms are mainly divided by the valve caliber, the purpose is to prevent the media to stop flowing or backflow, weakening the hydraulic impact.

Second, lift check valve: the valve flap along the body vertical centerline sliding check valve, lift check valve can only be installed in the horizontal pipeline, in the high pressure small diameter check valve on the valve flap can be used round ball. Lift check valve body shape and the same as the globe valve (can be common with the globe valve), so it has a large fluid resistance coefficient. Its structure is similar to the globe valve, and the valve body and valve flap are the same as the globe valve. The upper part of the valve flap and the lower part of the valve cover are processed with guide sleeve Jane, the valve flap guide Jane can be freely lifted in the valve jan guide Jane, when the medium flow, the valve flap by the medium thrust open, when the medium stop flowing, the valve flap by the self-hanging landing on the valve seat, play a role in stopping the medium backflow. Straight lift check valve media import and export channel direction and seat channel direction perpendicular; vertical lift check valve, the media import and export channel direction and seat channel direction is the same, the flow resistance is smaller than straight type.

Third, the disc check valve: the valve flap rotates around the pin in the valve seat check valve. Disc check valve structure is simple, can only be installed in the horizontal pipeline, the seal is poor.

Fourth, pipe-type check valve: the valve flap slides along the centerline of the valve body. Pipe-type check valve is a newly emerged valve, its small size, light weight, good processability, is one of the check valve development direction. However, the fluid resistance coefficient is slightly larger than the swing check valve.

Fifth, compression check valve: this valve is made for boiler feed water and steam cut-off valve, which has a lift check valve and globe valve or angle valve integrated function.

In addition, there are some check valves that are not suitable for pump outlet installation, such as bottom valve, spring type, Y type, etc.

1, in the piping system do not let the check valve bear the weight, large check valve should be independently supported so that it is not affected by the pressure generated by the piping system.

2, the installation of the direction of media flow should be consistent with the direction of the arrow marked on the valve body.

3, lift type vertical flap check valve should be installed in the vertical pipeline.

4、Lift type horizontal flap check valve should be installed in the horizontal pipeline.

| Valve body material | Nominal pressure (MPa) | Operating temperature (℃) | Applicable media | |

| Carbon Steel | 1.6-6.4 | ≤425 | Water, oil, steam | |

| 10.0-16.0 | ≤450 | |||

| Stainless Steel | P | 1.6-16.0 | ≤200 | Nitric acid |

| R | 1.6-16.0 | ≤200 | Acetic acid | |

| Chromium-nickel-titanium steel | PI | 1.6-6.4 | ≤550 | Petroleum, petroleum products |

| Chromium-molybdenum steel | 1.6-16.0 | ≤550 | Oil | |

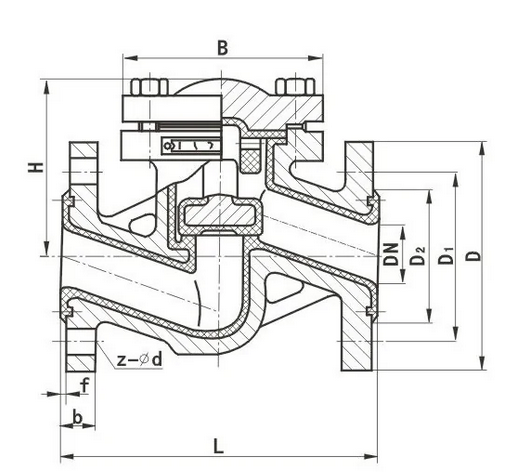

Lift check valve structure diagram

| Nominal pressure | Nominal diameter | Main connection dimensions | Shape Size | ||||||||

| PN | DN | L | D | D 1 | D 2 | D 6 | b | f | f 1 | Z-φd | H |

| 1.6MPa | 40 | 200 | 145 | 110 | 85 | - | 16 | 2 | - | 4-18 | 95 |

| 50 | 230 | 160 | 125 | 100 | - | 16 | 2 | - | 4-18 | 105 | |

| 65 | 290 | 180 | 140 | 120 | - | 18 | 2 | - | 4-18 | 120 | |

| 80 | 310 | 195 | 165 | 135 | - | 20 | 3 | - | 8-18 | 130 | |

| 100 | 350 | 215 | 180 | 155 | - | 20 | 3 | - | 8-18 | 140 | |

| 125 | 400 | 245 | 210 | 185 | - | 22 | 3 | - | 8-12 | 155 | |

| 150 | 480 | 280 | 240 | 210 | - | 24 | 3 | - | 8-23 | 180 | |

| 200 | 600 | 335 | 295 | 265 | - | 26 | 3 | - | 12-23 | 215 | |

The general valve iron swing check valve GB / T 13932-92

General valve steel swing check valve GB 12236 -2008

General valve iron globe valve and lift check valve GB 12233 -2006

Clamp check valve" JB/T 8937-2010

Steel Valves General Requirements" GB/T 12224-2005

The inspection and test of valves" JB/T 9092-1999

Building water supply and drainage and heating engineering construction quality acceptance specification" GB 50242-2002

Specification for Construction Quality Acceptance of Ventilation and Air Conditioning Works" GB50243-2002

01SS105 Commonly used small instruments and special valves selection and installation

(1) the quality control of the main blank all parts of the valve are forgings, forging in strict accordance with the forging process procedures and process cards, strict control of the starting forging temperature, final forging temperature, the degree of deformation and deformation speed, cooling according to the cooling method specified in the process procedures. Chemical composition analysis, mechanical property test, intergranular corrosion test and metallographic analysis are carried out on the forged products, and the analysis, test and determination are in accordance with the corresponding standards.

The quality of forgings is ensured by ultrasonic inspection and liquid penetration inspection. 100% ultrasonic flaw detection and evaluation of forgings are carried out according to the requirements of RCC-M, and liquid penetration inspection and evaluation of all surfaces of forgings are carried out.

(2) welding in order to improve the quality of overlay welding, the valve valve and seat sealing surface overlay welding using the plasma argon arc welding process. At the same time, in order to ensure the quality of welding, the welding process used in the production of the process re-evaluated.

(3) assembly test quality products not only need high-precision parts, more critical is how to assemble these high-precision parts into high-performance products. CNNC Su Valve organized an experienced and skilled assembly and commissioning team composed of a number of technicians and senior technicians, responsible for the assembly, commissioning and testing of the valve, the development of parts cleaning process, assembly process, strict control in the assembly and commissioning, excellence, to ensure the success of the valve assembly, commissioning, and various performance tests, the indicators are in line with the requirements of the design mission statement.

(4) process inspection of the valve prepared a quality plan to ensure that the valve from raw materials, blank input, machining, welding, heat treatment, non-destructive testing, cleaning, assembly, factory testing and various type tests are quality control, and the second research and design institute of nuclear industry approved and on-site witness.

Butterfly double-valve check valve is suitable for high-rise building water supply network, a certain chemically corrosive media network, installation space has limited pipeline network, also suitable for sewage pipeline network.

Lifting silent check valve is suitable for pipeline networks with high quality requirements for water supply and drainage projects; pipeline networks with relatively high pressure requirements (PN2.5Mpa); it can be installed at the outlet of the pump and is an economical and practical water hammer check valve.

Lifting anechoic check valve is suitable for water supply and drainage system, high-rise building pipeline network, can be installed at the outlet of the pump, with slight structural changes, can be used as a suction bottom valve, but not for sewage network.

Horizontal check valves are suitable for submersible, drainage and sewage pumps, especially for sewage and sludge systems.

Swing-open rubber check valve is suitable for use in domestic water pipeline network; however, it is not applicable to sewage with many sediments

Swing open single valve check valve is suitable for water supply system, petroleum, chemical, metallurgy and other industrial sectors are most suitable for places with installation space restrictions.

Check valve selection criteria are as follows.

1, in order to prevent the media backflow, in equipment, devices and pipelines should be installed check valve.

2, check valves are generally suitable for clean media, should not be used for media containing solid particles and high viscosity.

3, generally in the nominal diameter of 50mm horizontal pipeline should be selected horizontal lift check valve.

4, straight-through lift check valve can only be installed in the horizontal pipeline.

5, for the pump inlet pipeline, it is appropriate to use the bottom valve, the bottom valve is generally installed only in the vertical pipeline of the pump inlet, and the media flow from the bottom up.

6, lift type than the rotary type sealing, fluid resistance, horizontal should be installed in the horizontal pipeline, vertical installed in the vertical pipeline.

7, swing check valve installation location is not restricted, it can be installed in the horizontal, vertical or inclined pipeline, such as installed in the vertical pipeline, the media flow direction from the bottom up.

8, swing check valve should not be made into a small diameter valve, can be made into a very high working pressure, nominal pressure can reach 42MPa, and nominal diameter can also be very large, the maximum can reach more than 2000mm. According to the shell and seal materials can be applied to any working medium and any working temperature range. The medium is water, steam, gas, corrosive medium, oil, medicine, etc. Medium working temperature range between -196--800℃.

9, swing check valve for occasions is low pressure large diameter, and installation occasions are restricted.

10, butterfly check valve installation location is not restricted, can be installed in the horizontal pipeline, can also be installed in the vertical or inclined pipeline.

11, diaphragm check valve is suitable for easy to produce water strikes on the pipeline, diaphragm can well eliminate the water strikes generated by the media backflow, it is generally used in low-pressure room temperature pipeline, especially suitable for water pipelines, the general medium working temperature between -12 - 120 ℃, working pressure <1.6MPa, but the diaphragm check valve can be larger caliber, DN can reach a maximum of 2000mm or more.

12, spherical check valve is suitable for low and medium pressure pipeline, can be made into a large diameter.

13, the shell material of the spherical check valve can be made of stainless steel, the hollow sphere of the seal can be wrapped with PTFE engineering plastic, so in general corrosive media on the pipeline can also be applied, the working temperature between -101 - 150 ℃, the nominal pressure ≤ 4.0MPa, the nominal through range between DN200 - DN1200.

14, for incompressible fluids with check valve selection, the first step is to assess the required closing speed, the second step is to select the type of check valve that may meet the required closing speed.

15, for compressible fluids with check valve selection can be based on the incompressible fluids with check valves in a similar way to choose, if the media flow range is very large, the check valve for compressible fluids can be used a reduction device, if the media flow continuously and rapidly stop and start, such as the outlet of the compressor, then use the lift check valve.

16, check valve should determine the corresponding size, the valve supplier must provide information data on the selected size, so that the size of the valve can be found at a given flow rate when the valve is fully open.

17, for high and medium pressure check valves below DN50mm, it is appropriate to use vertical lift check valves and straight lift check valves.

18, for DN50mm or less of low pressure check valve, should use butterfly check valve, vertical lift check valve and diaphragm check valve.

19, for DN greater than 50 mm, less than 600 mm of high pressure check valve, it is appropriate to use the swing check valve.

20, for DN greater than 200mm, less than 1200mm of the low and medium pressure check valve, should be used for non-abrasive ball check valve.

21, for DN greater than 50mm, less than 2000mm low-pressure check valve, it is appropriate to use butterfly check valve and diaphragm check valve.

22, for the requirements of the closure of the water shock impact is relatively small or no water shock pipeline, it is appropriate to use slow-closing swing check valve and slow-closing butterfly check valve.

Caused by the valve flap breakage is

Check valve before and after the media pressure is close to the balance and each other "saw" state, the valve flap often beat with the valve seat, some brittle materials (such as cast iron, brass, etc.) made of the valve flap is broken.

Prevention is to use the valve flap for the tough material check valve.

The causes of backflow are

① sealing surface damage; ② entrapped impurities.

Repair the sealing surface and clean impurities, you can prevent backflow.

Contact US

Related Information

what type of flow does a globe valve giveCast Flow Check Valve3 Inch Check ValveBrass valvesWhere are solenoid valves usedhow a gate valve worksCheck Valve Cast Ironbutterfly valve symbolCast Iron Lift Check ValveCast Check Valvehigh performance butterfly valveButterfly Valvelug butterfly valve6 inch steel ball valvehow to identify gate and globe valvehigh pressure gate valves manufacturerwhat is ball valve in plumbingglobe valve flow controlChina Dual Plate Check ValveWhere would a single check valve be usedcontrol valve manufacturers chinatriple offset butterfly valve6 butterfly valveglobe valve partsglobe valve for steamsteam globe valveWhere is pressure relief valve usedhow does bellows seal globe valve workgate valve manufacturersNon Return Valve Suppliers Chinaglobe valve symbolsflow control globe valvewhat is a gate valvewhat is a globe valvehow to fix a leaking gate valveCast Iron Silent Check ValveCast Iron Non Return Valvepvc butterfly valveexhaust butterfly valveCast Iron Dual Plate Check ValveChina Check Valve Supplier3/4 ball valve for air compressorhow to repair gate valvestainless steel butterfly valveball valve working principle